Before embarking on a car restoration project, the restorer should be driven by a vision. That vision is of a vehicle that has been brought back from the brink -and has become a gleaming tribute to their hard work, persistence and probably considerable investment.

If you were to ask a serious restorer what their most satisfying moment was during the restoration, and they would almost always agree that it came when their mechanical system roared back into life after being dormant- possibly for decades.

If you were to ask a serious restorer what their most satisfying moment was during the restoration, and they would almost always agree that it came when their mechanical system roared back into life after being dormant- possibly for decades.

Restoring a vehicle’s mechanical system is undoubtedly the most complicated stage of the project involving dozens of moving parts that take in the engine, gearbox, clutch, camshaft, carburettor, cooling system, cylinder head, driveshaft and exhaust system.

Despite having to deal with all the issues to renew a vehicle’s mechanical systems, it is the area where most restorers feel most comfortable and where they can usually exert the most influence.

Statistics show that most people who take on a classic car restoration project have some hands-on experience working with mechanical systems- more than any other facet of a car restoration project.

Restorers have gained this experience– either tinkering around car engines in their spare time or have worked or are still employed as car mechanics.

Restorers enjoy the opportunity to work on their vehicle in their own workshop without the need to invest in expensive and often cumbersome equipment.

Restorers enjoy the opportunity to work on their vehicle in their own workshop without the need to invest in expensive and often cumbersome equipment.

Except in the most extreme cases, the mechanical systems in a classic UK or European car of the Fifties and Sixties will have remained physically intact, a testament to the car manufacturers of these times.

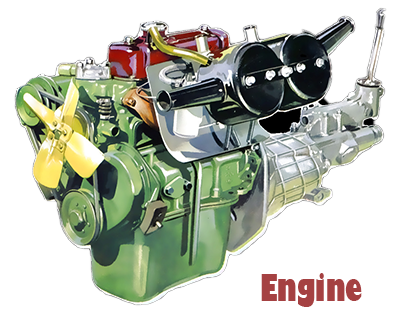

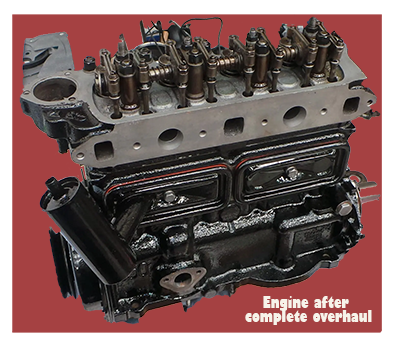

When it comes down to renovating a mechanical system, the engine will always be the first component to come under scrutiny.

It would be unreasonable to expect the machine to be in perfect running order and will likely need some attention.

This information will hopefully gathered during the pre-purchase assessment.

If the engine runs smoothly, the hope is that repairs and renewal costs will not be that high.

If it fails to turn over, then it will be more than likely that the engine has either seized, as the engine block has cracked or suffered severe malfunctions of a similar nature.

Its restoration will be more complicated, time-consuming and expensive.

Only a thorough workshop analysis will be able to determine the engine’s actual state of health.

The cost of engine repairs and rebuilds can only be based on the individual engine, although they can run from £1000 to £2500. If the model being restored is either obscure or upmarket ( or even both), the cost can reach as high as £5000 for a total rebuild.

![]()

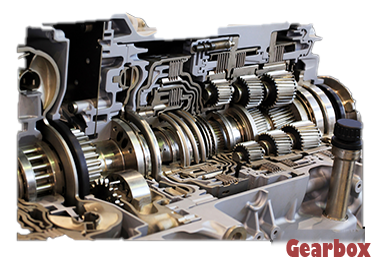

While the engine is the heart of any vehicle, the gearbox plays no less important role. Most UK and European cars of the Fifties and Sixties came with manual transmission, automatic gearboxes being rare.

Driving some of the larger saloons of the Fifties fitted with a manual gearbox could be a challenge.

An investment that will almost always make for an immensely more pleasurable driving experience.

If the car was in running order pre-purchase and the gearbox is in good running order, quiet, with efficient synchromesh and does not jump out of gear, little will need to be done.

Unfortunately, the rule of thumb states that if the car engine is in a state of disrepair, the gearbox will be in a similar condition, with the rigours of old age or misuse having played their part.

Once again, a proper analysis of the gearbox’s state of repair is a must.

If the gearbox is found to be repairable and the restorer has the skills and tools to do so in-house, then this is always the preferable option.

If the the necessary skills or relevant workshop facilities are not on hand, then the restorer will be well advised to save themselves a lot of time and aggravation by investing in aftermarket or reconditioned unit, contenting themselves with reassembling the drivetrain and reinstalling it in their car- always an exciting moment!

![]()

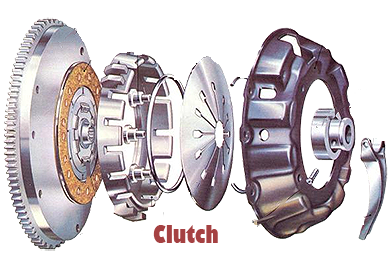

The third and no less critical component to be scrutinised is the clutch. As stated, most Fifties UK and European cars came fitted with a manual transmission as standard meaning that a clutch was a necessity.

The clutch is the least complicated component of the drivetrain, and therefore the easiest to repair and, if need be, to replace.

From the mid-Thirties running on to the late Fifties a single plate clutch was fitted to practically all British and European cars in the mainstream category.

From the mid-Thirties running on to the late Fifties a single plate clutch was fitted to practically all British and European cars in the mainstream category.

As its title suggests carrying out a rebuild on a single plate clutch is a relatively simple process. The first step is to identify and examine the thrust springs and ensure that they are all the same height.

Evidence of the clutch having overheated should be checked for, with a sure sign being that the coils will be discoloured. If this is the case, then the coils will need to be replaced.

Other major components of the mechanical system of any classic, the cooling system, fuel system, points and plugs, air and water filters will need to be restored to allow a classic car’s mechanical systems to perform to their maximum capabilities.

Other major components of the mechanical system of any classic, the cooling system, fuel system, points and plugs, air and water filters will need to be restored to allow a classic car’s mechanical systems to perform to their maximum capabilities.

The aspirations of any classic car restorer, from the rawest beginner to the most experienced, should always be to return their classic car’s mechanics to the standard when it rolled off the production line – if not improve on it.

Take me back to the home page.

me5