Bringing a classic car back to a condition where it can be classed as roadworthy by the relevant authorities is a responsibility that cannot be taken lightly. To put the vehicle back on the road means renewing or restoring to the underbody of the vehicle- in particular, its brakes, suspension with steering a priority.

Bringing a classic car back to a condition where it can be classed as roadworthy by the relevant authorities is a responsibility that cannot be taken lightly. To put the vehicle back on the road means renewing or restoring to the underbody of the vehicle- in particular, its brakes, suspension with steering a priority.

If the vehicle being scrutinised before purchase is in running order, this is a significant advantage as the restorer will gain a clearer picture of the state of health of the vehicle's underbody.

If the vehicle being scrutinised before purchase is in running order, this is a significant advantage as the restorer will gain a clearer picture of the state of health of the vehicle's underbody.

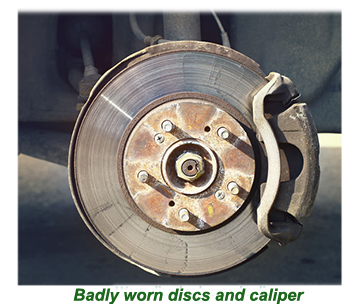

The first item to test is the brakes. Brakes in good order will mean that the car should stop smoothly with no fading (diminishing of stopping power), and it should track in a straight line.

Any grinding or scraping noises will indicate that the brakes may be worn down past the linings and need to be replaced.

If the vehicle pulls to one side or the pedal goes down slowly, the hydraulic system may likely have sprung a leak.

A handy visual guide is to check the back of each wheel for signs of leaking brake fluid. Leaks can also be common around the master cylinder.

Next is to test the steering, and if possible, under a few different conditions. If the steering wheel starts to shudder severely at certain speeds, this is an almost sure sign that the front end will need a rebuild.

![]()

Excessive play in the steering wheel before the car starts to tum will mean that the steering linkage may be worn, or the steering box may need an overhaul.

If the vehicle is a "non-runner" that has been standing for many years, the restorer can safely assume that a major overhaul to all the underbody systems is on the cards. The fact that the vehicle is a non-runner should be considered in the seller's asking price.

It is a fact that while most amateur mechanics will know their way around an engine, a lot less will possess the necessary knowledge and experience to work on a vehicle's underbody.

It is a fact that while most amateur mechanics will know their way around an engine, a lot less will possess the necessary knowledge and experience to work on a vehicle's underbody.

A factor that will make it more or less certain than the task of renewing the three significant systems be placed in professional hands.

Most UK and European classic cars of the Fifties and the early Sixties came fitted with drum brakes in the front, which were considered cumbersome and outdated.

Unless the restorer is a stickler for authenticity, they will follow the trend to replace the drums with discs, which are so much better in many ways and will not cost a fortune to replace.

If the restorer has a large budget and intends to fit a more powerful engine, they should consider installing power-assisted brakes. However, it will be an unnecessary expense if the car's power is not to be increased.

![]()

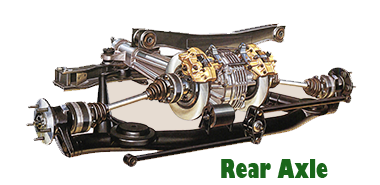

The primary purpose of a car's suspension is to keep all four wheels on the road. Even if the vehicle is riding on the finest of tyres after the restoration, they will provide precious little in the way of roadholding if the suspension is not spot on.

If the model being restored is from the Sixties and sold in large quantities in its day, original replacements may still be available, although liable to be expensive. If the model is more obscure , especially one that goes back to the Fifties, will be impossible to trace, and the only likely alternative will begin to source aftermarket parts.

There is no reason to panic as costs for aftermarkets parts are typically low, while quality is reasonably high.

The same procedures apply to the vehicle's shock absorbers. Going back to the pre-war years, hydraulic shock absorbers were popular and remained so until the Sixties. It was then that they were replaced by telescopic shock absorbers, which are popular today.

When a vehicle's wheel goes over a bump in the road, the suspension spring allows for adjustment allowing the vehicle floor to remain level.

When a vehicle's wheel goes over a bump in the road, the suspension spring allows for adjustment allowing the vehicle floor to remain level. The suspension spring provides essential movement for the wheels while the shock absorber act as a form of vibration damper for the spring.

Hardly any system connects the driver so directly to their vehicle than its steering. A variety of mechanical solutions exist to make the car change direction as the driver wishes.

![]()

Nearly all common types of steering follow the so-called 'Ackermann' principle, developed by the renowned German of hat same name more than two hundred years ago. The revolutionary principle behind the Ackermann theory is that the axle itself does not turn the vehicle, instead the front wheels.

Hardly any system connects the driver so directly to their vehicle than its steering.

A variety of mechanical solutions exist to make the car change direction as the driver wishes.

Most European and UK cars of the Fifties and Sixties were fitted with rack and pinion steering.

Hardly any system connects the driver so directly to their vehicle than its steering.

A variety of mechanical solutions exist to make the car change direction as the driver wishes.

Most European and UK cars of the Fifties and Sixties were fitted with rack and pinion steering.

Since in general use today, rack and pinion steering has consistently proved to be not only practical, compact as well as inexpensive to fit and maintain.

Since in general use today, rack and pinion steering has consistently proved to be not only practical, compact as well as inexpensive to fit and maintain. In smaller family saloons and sports tourers, there is no real reason to change anything, only to ensure that the system is in the best working condition.

Most larger saloons of the Fifties and Sixties were famous for their cumbersome steering. Restorers who want to improve their driving experience often consider fitting power steering.

Power steering will dramatically improving their driving experience, especially if the car is driven in the city.

Power steering will dramatically improving their driving experience, especially if the car is driven in the city. Once again, the fundamental decisions on how to bring the car's suspension up to the levels required to make it roadworthy and pleasant to drive will only really be taken in the workshop during the initial pre-renovation inspection.

The restoration project leader will need to bear in mind that the chances are that most of the underbody renovation will need to be farmed out to specialists and can be costly.

Take me back to the home page.