One of the focal points of any car interior is its dashboard, with the current design format remaining intact for close to a century.

One of the focal points of any car interior is its dashboard, with the current design format remaining intact for close to a century.

Early dashboards were almost exclusively crafted with wood, usually veneers, giving the cars of those times a naturally luxurious feel that was not always justified.

Early dashboards were almost exclusively crafted with wood, usually veneers, giving the cars of those times a naturally luxurious feel that was not always justified.

Classic car restorers rapidly discovered that wooden dashboards and trim rarely stand the test of time. If not lovingly maintained, the wooden trim will deteriorate with the veneer perishing, calling for a complete restoration.

Restoring a wooden dashboard is a procedure that can rarely be accomplished in-house and will demand a lot of time and considerable expense.

The first stage in the replenishment process is the removal of the original lacquer finish.

The first stage in the replenishment process is the removal of the original lacquer finish.

Restoring lacquer to its original finish is a time-consuming endeavour as sanding is not an option, with the risk of damaging the delicate layer of veneer underneath is extremely high.

Instead, equal parts of denatured alcohol and lacquer thinner should be gently applied using a clean paintbrush that will 'eat' away the old finish.

Once the lacquer has been removed, if the veneer surface appears to be in good condition, all required is to apply a fresh coat of lacquer, although gingerly.

Once the lacquer has been removed, if the veneer surface appears to be in good condition, all required is to apply a fresh coat of lacquer, although gingerly.

If the veneer is damaged in any way, an expert should be called in to assess if the dashboard can be saved.

Typical damage to a wooden dashboard usually involves the veneer splitting in the middle or coming loose around the edges.

If these problems are not advanced, the damaged areas can be sent for repair by one of the remaining UK or Western European companies that are still active in the restoration of wooden trim.

If the veneer on the dashboard is damaged beyond repair, it is possible to replace it, matching the grain as accurately as possible to the original - if a sample from the original veneer is available.

For anyone brave enough to consider going it alone in refurbishing natural wood trim parts, these specialist suppliers who will gladly provide the veneers, adhesives and lacquers to do the job.

![]()

Companies that provide such a service have been around for decades and are professional and proficient enough to custom cut the dashboard so that every gauge and clock will have its place- in line with the original layout.

Metal dashboards began to com into vogue in the immediate post-war years with the advent of mass production combined with the shortage of wood.

Metal dashboards began to com into vogue in the immediate post-war years with the advent of mass production combined with the shortage of wood.

If the body of the vehicle being restored has remained intact, metal dashboards should be rust free. In most cases, all that is required is to apply a fresh coat of paint to match the rest of the vehicle.

In recent years, to recapture the pre-war mood, a number of restorers have taken the brave step of painting the metal on the dashboard in a wood effect that can also take in door trims and window surrounds.

Unless the restorer is genuinely talented in that direction, the chances of coming up with a finish indistinguishable from natural wood are not that high.

However, they can still create a semi-exclusive effect sadly missing in the austerely trimmed mass-market cars of the Fifties.

The simple key to creating a wood effect topcoat is always to apply paint in one direction (preferably up and down), creating the effect of wood grain, although sparse quantities of paint should be applied on each stroke.

Hand painting a metal dashboard will undoubtedly save money but will rarely resemble the real thing.

![]()

An alternative, recently introduced, and possibly more appealing is aftermarket wood grain effect dashboards. These dashboards are inexpensive, functional, and can readily be fitted on most UK and European Fifties and sixties cars.

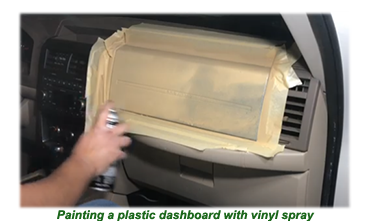

From the Sixties and onwards, vehicles in the medium budget range came with dashboards fabricated from extruded plastic. This new style of dashboards appealed to everyone, being attractive and exceptionally durable, and proved themselves long term as they aged particularly well.

From the Sixties and onwards, vehicles in the medium budget range came with dashboards fabricated from extruded plastic. This new style of dashboards appealed to everyone, being attractive and exceptionally durable, and proved themselves long term as they aged particularly well.

The only possible flaw in an extruded plastic dashboard was that their paintwork was liable to fade over the years, depending on how much sunlight they were exposed to over the year.

Bringing an extruded plastic dashboard back to its optimal level will require a little effort as plastic surfaces, being oil-based, requires mechanical bonding rather than chemical bonding used when painting metal surfaces.

Preparation for painting plastic dashboards can be a challenge, requiring a slightly different approach.

Preparation for painting plastic dashboards can be a challenge, requiring a slightly different approach.

The first stage is to scuff the surface with sandpaper, with particular scrutiny needed as to how coarse the sandpaper should be.

Overzealous sanding could cause irreparable damage, so it's best for the restorer to take a few trial runs on a limited area till they hit the proper formula.

After the long and labour-intensive stage is over, the dash will be ready for a coat or two of primer.

Once the primer has been given sufficient time to dry, the final stage is spraying the new paint with at least two coats that should be resin-based and rapidly absorbed into the plastic.

Once the primer has been given sufficient time to dry, the final stage is spraying the new paint with at least two coats that should be resin-based and rapidly absorbed into the plastic.

If the steps involved have been followed, the refurbished dashboard should look as good as when it left the production plant seventy years or more ago.

int 4