Classic car lovers may find it difficult to believe that as recently as forty years ago, the only dashboard instrument that came as standard, required by law to be fitted on a vehicle dashboard was the speedometer.

Classic car lovers may find it difficult to believe that as recently as forty years ago, the only dashboard instrument that came as standard, required by law to be fitted on a vehicle dashboard was the speedometer.

Any additional instruments could be fitted at the owner's discretion.

Many did so, simply punching a hole through the dashboard to which the gauge was inserted and in many cases remaining unattached to create a dramatic effect.

Many did so, simply punching a hole through the dashboard to which the gauge was inserted and in many cases remaining unattached to create a dramatic effect.

The various dials and gauges found on a classic automobile were expected to last the active life of the vehicle, estimated to be about ten years or one-hundred thousand miles at the most.

These early instruments were not designed to be serviceable and certainly not repairable, developed and assembled haphazardly.

These early instruments were not designed to be serviceable and certainly not repairable, developed and assembled haphazardly.

Car manufacturers of these times could never have considered the wave of nostalgia that began to gain momentum in the Eighties, with hundreds if not thousands of car lovers rushing to find cars of their youth to restore.

While every aspect of classic car restoration has its exciting aspects, restoring a vehicle's instruments and gauges seems to hold a lot of mystique- and the options are considerable.

Anyone with the time, ability and patience to restore the external facades of their clocks and gauges are sure to find it a rewarding task. Sadly, most restorers do not possess all or any of these qualities, meaning they turn to the many UK and European companies who provide the service.

Anyone with the time, ability and patience to restore the external facades of their clocks and gauges are sure to find it a rewarding task. Sadly, most restorers do not possess all or any of these qualities, meaning they turn to the many UK and European companies who provide the service.

Refurbished and replicate clocks and gauges are readily available off-the-shelf, with a number of them in digital format although identical in their external appearance to the original.

The speedometer

The speedometer is regarded as the most important gauge on any vehicle dashboard yet varies from the others as part of the electrical system.

Driven by a rotating cable, The speedometer is in turn driven by the car's gearbox.

![]()

Where the cable meets the speedometer, it turns a magnet inside a metal drum.

As the magnet spins, it attracts the drum and causes it to rotate.Attached to the drum are the speedometer needle and a return spring. The faster the magnet rotates, the further across the gauge the needle swings.

The most typical fault that can occur with a speedometer is a worn cable, rapidly brought back to working condition by applying a little light oil.

The Odometer

No less an essential gauge than the speedometer, the odometer is linked to the speedometer and driven by the same rotating cable and is nothing more than a simple mechanical counter.

No less an essential gauge than the speedometer, the odometer is linked to the speedometer and driven by the same rotating cable and is nothing more than a simple mechanical counter. Notoriously inaccurate in cars that have been around for decades, most restorers prefer to replace the odometer with a restored or brand-new version that has been reset to zero. If the vehicle's accurate mileage can authenticate for any reason, then the odometer can be set to the current figure. If the engine is being overhauled or replaced, the mileage should be set back to zero

Temperature gauge

The temperature gauge utilises a sensor adjacent to the thermostat housing that provides an accurate update on the vehicle's cooling system by transmitting a signal to the gauge with a reading of the current temperature.

The temperature gauge utilises a sensor adjacent to the thermostat housing that provides an accurate update on the vehicle's cooling system by transmitting a signal to the gauge with a reading of the current temperature. There are two types of temperature gauges, electric and mechanical. Modern cars are fitted with electrical gauges, although most Fifties and Sixties cars were equipped with a mechanical gauge, driven by a device known as a Bourdon Tube.

Made up either from brass or copper, the Bourdon Tube is filled with a fluid that easily vapourises, usually alcohol.

![]()

Sealed at both ends, the end nearest the gauge is formed into a spiral whose end is attached to the indicating needle while the other is fitted to a water-tight connector in direct contact with the coolant in the engine.

Sealed at both ends, the end nearest the gauge is formed into a spiral whose end is attached to the indicating needle while the other is fitted to a water-tight connector in direct contact with the coolant in the engine.

As the coolant warms up, the fluid in the tube expands, transfers its force to the coiled end of the tube, which, as it unwinds, applies contra to the needle, reflecting the temperature reading on the gauge face.

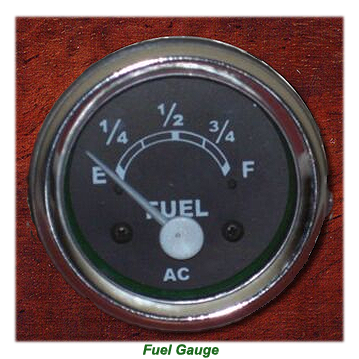

Fuel gauge

The fuel gauge is operated by variable resistance, in a similar method to the temperature gauge.

A bimetallic strip causes the gauge needle to move as the voltage within the sender unit alters.

The sender unit is mounted within the petrol tank, consisting of a float attached to a coil which acts as a variable resistor.

As the float rises and falls, the amount of resistor in the circuit alters, relaying the position of the fuel level to the instrument panel.

Oil pressure gauge

An oil pressure gauge operates through oil being sent to the gauge through a narrow pipe, placed so that it cannot be punctured, a catastrophe that could destroy the car's engine if all the oil leaks out.

The gauge itself contains a flexible coiled tube, with the open end rigidly attached to the gauge's outer casing.

The gauge itself contains a flexible coiled tube, with the open end rigidly attached to the gauge's outer casing.

The other end of the tube, which is sealed, is connected to the bottom end of the needle.

Oil is fed into the tube ( sometimes known as a bulb) at an almost equal pressure maintained in the engine.

Oil is fed into the tube ( sometimes known as a bulb) at an almost equal pressure maintained in the engine.

The bulb will minutely straighten under pressure, with the force generated sufficient to move the needle around the calibrated gauge scale.

The greater the oil pressure, the more the needle moves, providing the driver with an up to date picture.

The greater the oil pressure, the more the needle moves, providing the driver with an up to date picture.

Most dashboards are fitted with a simple time clock, which has progressed through time from the traditional mechanical method to the digital timepiece of today.

int 4