The driveshaft is among the most overlooked components of a mechanical system, despite playing an especially important part in its operation.

The driveshaft is among the most overlooked components of a mechanical system, despite playing an especially important part in its operation.

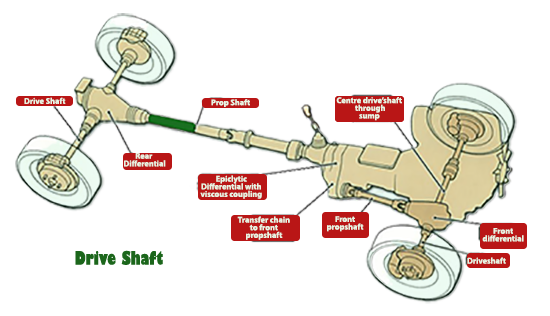

In simplest terms, the driveshaft is the shaft that drives the vehicle- between its engine and its rear wheel, as front-wheel drive vehicles do not need a driveshaft.

To properly assess and replace the driveshaft, it is essential to thoroughly inspect all of its components. This includes examining the universal joints, center support bearing, and slip yoke. Substitute any components that have incurred damage or experienced wear and tear with brand new replacements. To ensure optimal reliability and safety of the driveshaft, it is imperative to utilize replacement parts of superior quality.

To properly assess and replace the driveshaft, it is essential to thoroughly inspect all of its components. This includes examining the universal joints, center support bearing, and slip yoke. Substitute any components that have incurred damage or experienced wear and tear with brand new replacements. To ensure optimal reliability and safety of the driveshaft, it is imperative to utilize replacement parts of superior quality.

Balancing the driveshaft is of utmost importance to effectively mitigate vibration and minimize potential driveline complications. Most driveshaft repair shops possess the essential equipment required to effectively balance the driveshaft.

While front-wheel drive traverse engined vehicles enjoyed considerable popularity during the Sixties with the advent of the compact car, most of the vehicles produced during the Fifties and Sixties were rear-wheel drives.

In a rear-wheel drive vehicle, the gearbox and axle are separate units, meaning that the transmission's turning motion is transferred to the rear axle via the driveshaft.

Driveshafts of the Fifties and Sixties were produced from either steel or aluminium.

Driveshafts of the Fifties and Sixties were produced from either steel or aluminium.

In recent years carbon fibre has increasingly become the material of choice in driveshaft construction .

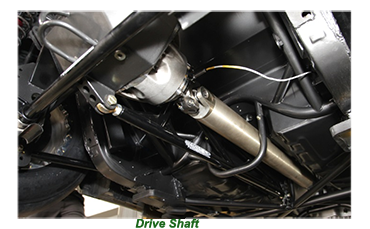

Most vehicular drive shafts are hollow and tubular in design, ensuring that they will be lightweight, flexible and robust enough to survive an anticipated life span of at least ten years.

Most driveshafts in classic cars were produced as a single unit, although there were a few models released with a two-piece crankshaft.

Most driveshafts in classic cars were produced as a single unit, although there were a few models released with a two-piece crankshaft.

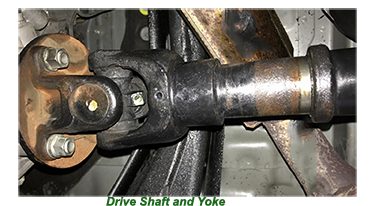

On a single piece driveshaft, the connection between the transmission to the axle is made through a piece of equipment known as a slip yoke.

The yoke is designed to easily slide over the slats on the transmission's output shaft.

During a journey, the driveshaft's motion will allow it to slide back and forward to prevent the units from binding through the use of universal joints that buffer between the yoke and the driveshaft.

Universal joints or u-joints are better known as the connecting point between the differential and driveshaft. The U-joints' role is to adjust itself to allow the vehicle to always travel at the correct angle.

![]()

When considering a classic car for restoration, the following symptoms of actual or potential driveshaft problems should be sought out.

The first and most likely source of the issues that arise is long term wear and tear coupled with corrosion.

Both of these issues are more likely to raise their heads if the vehicle has been standing for a long time.

Both of these issues are more likely to raise their heads if the vehicle has been standing for a long time.

These problems should not put off anyone considering a particular vehicle for restoration. Restoring or even fully replacing a driveshaft or its constituent parts is neither expensive nor difficult to implement.

If the vehicle under scrutiny is capable of travelling under its own impetus, then, as ever, a test drive is a must.

One of the problems that may turn up during a test drive is when the vehicle begins to shudder and vibrate from the driveshaft's general direction.

This fault can often be nothing more than a minor inconvenience caused by the driveshaft coming loose slightly from the U-joints or being knocked slightly out of balance.

In any event, a few minutes of adjustment should get the driveshaft back on track in the majority of cases.

If a series of loud clunking and popping sounds can be heard from the vehicle's underside is a sign that the bearings inside the U-joints have begun to wear out.

If a series of loud clunking and popping sounds can be heard from the vehicle's underside is a sign that the bearings inside the U-joints have begun to wear out.

Unfortunately, this is a very strong indication that the entire U-joint will need to be replaced.

![]()

Another symptom of the same problem when the vehicle being tested does not corner without difficulty due to heavy steering. Once again, it is off to the workshop to investigate the full extent of the problem, which will almost inevitably lead to either repairing or replacing the driveshaft.

Repairing or replacing a vehicle's driveshaft as well as the yokes and u-joints is almost always carried out in a single operation.

Repairing or replacing a vehicle's driveshaft as well as the yokes and u-joints is almost always carried out in a single operation.

Before going ahead, it is worth taking a few minutes to ensure that one or more of these parts cannot be saved as they are all interchangeable.

Removing a driveshaft is very straightforward, requiring only the most basic hand tools, including a socket wrench and socket set and box wrenches.

It may be necessary to have a crowbar on hand if the driveshaft proves challenging to release.

Removing the U-Joints from the yokes could be a lot tougher and will probably require the services of a specialist piece of equipment known as a bearing press, as the caps of the U-joints' caps need to be pressed into the yokes.

In the likely event that a bearing press is nowhere around, access to a bench vice and a socket send might do the job, although involving considerably more effort and the risk of damaging the parts.

In the likely event that a bearing press is nowhere around, access to a bench vice and a socket send might do the job, although involving considerably more effort and the risk of damaging the parts.

As always should be the case, anyone involved in a classic car restoration should be capable of making the decision whether they have the necessary skills, patience and equipment to repair or replace a faulty driveshaft, yoke or U-joints or take the easy and often wise decision to farm out the job to professionals.

Take me back to the home page.

ub6