The icing on the cake for any restoration project is completing the vehicle's external trim.

The icing on the cake for any restoration project is completing the vehicle's external trim.

From the mid-Fifties, the problems of short supply of raw materials in the car industry were all but over.

From the mid-Fifties, the problems of short supply of raw materials in the car industry were all but over.

Every car lover will agree that nothing looks more impressive than a classic car with lots of chrome can look very impressive- as long as it is not overdone.

Every car lover will agree that nothing looks more impressive than a classic car with lots of chrome can look very impressive- as long as it is not overdone.

History has shown that chrome trimmings and the UK and European weather conditions were not an ideal match, especially as the region's various governments were very inclined to lay down abundant quantities of raw salt during the winter months.

Anyone taking on a car restoration project will probably be aware that one day in the not-too-distant future, the problem of chrome trim renewal will rear its head.

Anyone taking on a car restoration project will probably be aware that one day in the not-too-distant future, the problem of chrome trim renewal will rear its head.

They should be ready with an open cheque book and at least some knowledge, if not experience, of what will be required to bring their chrome trim back to its glory days.

Chromes describes a technique of electroplating a thin layer of chromium onto a metal object,particularly steel, and is used only for a decoration .

The chrome will begin to oxidise almost immediately when exposed to a combination of oxygen and water. When it does , the first signs of rust and pitting will begin to show.

![]()

When embarking on a restoration project, the first step should always be to strip the restoration vehicle of all its exterior trim.

Particular attention should be paid to the chrome, which may be vulnerable. All parts should be labelled and photographed while on the vehicle and again after being removed for ease of identification.

While it may seem the least urgent of all the stages of the restoration project, it is good advice to get cracking immediately on renewing the chrome- deciding which parts require only minor repair or a good buffing, which parts need to be renewed and which parts cannot be repaired, and replacement parts ordered.

While it may seem the least urgent of all the stages of the restoration project, it is good advice to get cracking immediately on renewing the chrome- deciding which parts require only minor repair or a good buffing, which parts need to be renewed and which parts cannot be repaired, and replacement parts ordered.

A procedure that can take a lot of time.

If the model being restored is one of the more popular around during the Fifties or the Sixties, it might be possible and even affordable to order reconditioned parts that have undergone rechroming.

If the model being restored is one of the more popular around during the Fifties or the Sixties, it might be possible and even affordable to order reconditioned parts that have undergone rechroming. This is a worthwhile option,although only worth considering if the original parts are beyond saving.

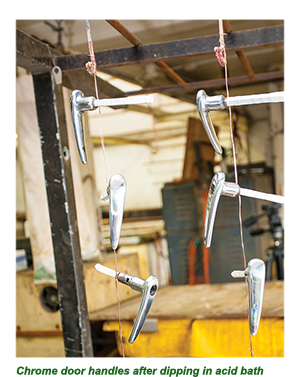

In the likely event that neither of these options are possible, then all roads lead to the acid bath. A procedure that most restorers rarely feel comfortable about taking but has proven to be the most effective.

All that is required is for the restorer to source one of the specialist UK companies who offer these services. Rather than travelling the length and breadth of the company with the parts to be rechromed, a lot of time and expense can be saved by circulating the digital images of the parts to be renewed around these companies to get an idea of price as well as delivery times- which can sometimes be considerable.

![]()

Once the decision has been made as to which company will be given the job, all of the parts can be put in the back of a van and off to the chromers we go.

If the restorer has the time, they should take the opportunity observe the many stages of the rechroming process.

The first stage involves stripping the chrome surface electro-chemical that will remove all of the original plating as well as any rust that has accumulated over the years.

The first stage involves stripping the chrome surface electro-chemical that will remove all of the original plating as well as any rust that has accumulated over the years.

The parts will have been rendered back to bare metal with all the flaws exposed.

The parts will have been rendered back to bare metal with all the flaws exposed.

The next stage is for the metal parts to go through a process known as linishing, which will bring the metal to a clean and flat state. All the damages to the metal will be repaired, after which it goes through another cleaning making for a surface that is smooth and shiny – ready for electroplating.

Electroplating metal involves applying an electrical charge, using copper plate that draws the nickel onto the surface, giving the chrome its silver-like appearance. Professional chrome platers will always apply dual coats of nickel.

Electroplating metal involves applying an electrical charge, using copper plate that draws the nickel onto the surface, giving the chrome its silver-like appearance. Professional chrome platers will always apply dual coats of nickel.

Once the nickel plating is completed and the nickel polished, a final chrome coating is added, in a process known as 'triple plate chrome'.

>Restorers who set up a budget for rechroming should be prepared to wait at least a month for the job to be completed.

ex5