The battery plays an unsung part in any vehicle's auto electrical system, requiring roughly 25 amperes of current when the car's electrics are working flat out, usually at night with its lights on.

The battery plays an unsung part in any vehicle's auto electrical system, requiring roughly 25 amperes of current when the car's electrics are working flat out, usually at night with its lights on.

That rate of current draw would run the battery flat within an hour or two unless there is some way to recharge the battery with the engine running where the alternator comes into play.

When carmakers first began installing starter motors and electrical systems on automobiles, they installed belt-driven generators to re-supply the battery with voltage.

Generators are electric motors being mechanically driven to generate current rather than being electrically powered.

Generators are electric motors being mechanically driven to generate current rather than being electrically powered.

A mechanical voltage regulator kept the charging voltage relative constant over the operating range of engine rpm, and if everything was working correctly, the battery stayed nicely charged.

A mechanical voltage regulator kept the charging voltage relative constant over the operating range of engine rpm, and if everything was working correctly, the battery stayed nicely charged.

Alternators first began to replaced generators during the Fifties, highly in demand as they were smaller, lighter, and more efficient.

Apart from generators, alternators produce alternating current (AC) rather than direct current (DC), which previously powered the vehicle's electrical system.

To actually recharge or chemically reverse the discharge process in the battery, the charging system must produce voltage about 2 volts higher than the battery's roughly 12.5 volts.

![]()

This higher voltage forces amperage back into the battery, so to speak, reversing the chemical reaction and recharging the battery.

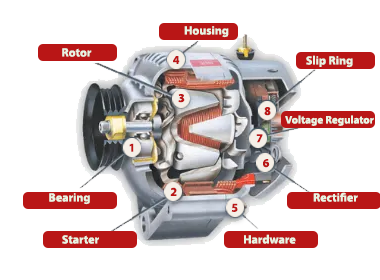

The voltage regulator, whether the electrical device stands alone in the engine compartment or, more commonly, is built into the alternator itself or, more recently, is incorporated into the powertrain control module (PCM)-the engine management computer itself-does precisely what its name describes.

The voltage regulator, whether the electrical device stands alone in the engine compartment or, more commonly, is built into the alternator itself or, more recently, is incorporated into the powertrain control module (PCM)-the engine management computer itself-does precisely what its name describes.

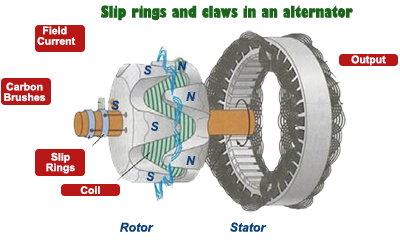

Turning on and off the field current to the rotating field/armature in the alternator regulates output voltage in that 13-15-volt range controlling the recharging voltage to the battery.

Voltage regulator failure can either allow the battery to discharge as the vehicle is operated progressively or overcharge and kill the battery by supplying an overly high, unregulated voltage due to a component failure in the regulator.

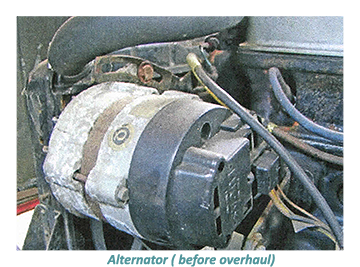

Driven by a form of serpentine belt, the alternator, regarded as a maintenance-free unit, should last for between ten to fifteen years of normal use without the need for repair or replacement.

When the alternator does begin to fail, its increasing effects will not immediately be felt as the vehicle will run on the power of the battery till switched off.

![]()

The battery plays an unsung part in any vehicle's auto electrical system, requiring roughly 25 amperes of current when the car's electrics are working flat out, usually at night with its lights on.

That rate of current draw would run the battery flat within an hour or two unless there is some way to recharge the battery with the engine running where the alternator comes into play.

When carmakers first began installing starter motors and electrical systems on automobiles, they installed belt-driven generators to re-supply the battery with voltage.

Generators are electric motors being mechanically driven to generate current rather than being electrically powered.

A mechanical voltage regulator kept the charging voltage relative constant over the operating range of engine rpm, and if everything was working correctly, the battery stayed nicely charged.

A mechanical voltage regulator kept the charging voltage relative constant over the operating range of engine rpm, and if everything was working correctly, the battery stayed nicely charged.

Alternators first began to replace generators during the Fifties and were highly in demand from their launch, being smaller, lighter, and more efficient.

Apart from generators, alternators produce alternating current (AC) rather than direct current (DC), which previously powered the vehicle's electrical system.

To actually recharge or chemically reverse the discharge process in the battery, the charging system must produce voltage about 2 volts higher than the battery's roughly 12.5 volts.

![]()

This higher voltage forces amperage back into the battery, so to speak, reversing the chemical reaction and recharging the battery.

The voltage regulator, whether the electrical device stands alone in the engine compartment or, more commonly, is built into the alternator itself or, more recently, is incorporated into the powertrain control module (PCM)-the engine management computer itself-does precisely what its name describes.

Turning on and off the field current to the rotating field/armature in the alternator regulates output voltage in that 13-15-volt range controlling the recharging voltage to the battery.

Voltage regulator failure can either allow the battery to discharge as the vehicle is operated progressively or overcharge and kill the battery by supplying an overly high, unregulated voltage due to a component failure in the regulator.

< Driven by a form of serpentine belt, the alternator, regarded as a maintenance-free unit, should last for between ten to fifteen years of normal use without the need for repair or replacement.

Driven by a form of serpentine belt, the alternator, regarded as a maintenance-free unit, should last for between ten to fifteen years of normal use without the need for repair or replacement.

When the alternator does begin to fail, its increasing effects will not immediately be felt as the vehicle will run on the power of the battery till switched off.

The usual warning sign that all is not well in the vehicle's charging system is a battery-shaped warning light that can even come on while driving. If it stays on, it is an almost certain indication that there is a problem with the vehicle's charging system. The charging system warning light does not always point directly to a failed alternator. However, alternator problems are prevalent, meaning a visit to a mechanic will be required to pinpoint the problem with the part.

Another symptom of alternator trouble is a buzzing noise coming from the alternator, although in some cases, this could be caused by a noisy alternator bearing.

The charging system warning light does not always point directly to a failed alternator. However, alternator problems are prevalent, meaning a visit to a mechanic will be required to pinpoint the problem with the part.

Another symptom of alternator trouble is a buzzing noise coming from the alternator, although in some cases, this could be caused by a noisy alternator bearing.

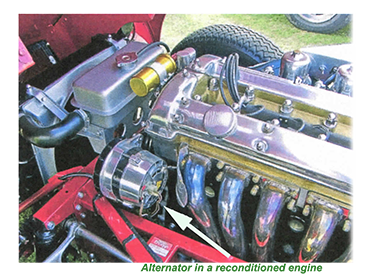

If the faulty alternator can be rebuilt, cost-saving will be considerable, as replacing an alternator aftermarket part can cost between £300 to £500 with original equipment manufacturer (OEM) considerably more expensive.

If the faulty alternator can be rebuilt, cost-saving will be considerable, as replacing an alternator aftermarket part can cost between £300 to £500 with original equipment manufacturer (OEM) considerably more expensive.

Restorers who have the time and ability to carry out their alternator repairs and reinstallation in-house can give their budget a boost by investing in an alternator rebuild kit - available online at a price between £10-£40.