One of the most significant moments in any car renovation project is when the proud owner turns the key in the ignition system for the first time.

One of the most significant moments in any car renovation project is when the proud owner turns the key in the ignition system for the first time.

That's the reason why special care and attention has to be paid to repairing and renovating the classic car's ignition system not only for the first time it has to be in operation but for all the many years that they will be on the road after.

Failure or negligence to restore and maintain the system will lead to a vehicle that will be at best unreliable and make for an unpleasant ride.

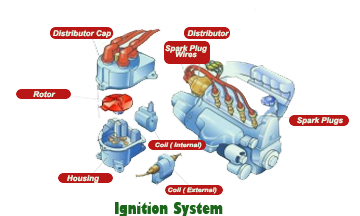

The role of the ignition system is simple: to produce a spark to ignite the mixture of fuel and air released by the carburettor and deliver this spark at the correct time. To achieve this is no simple task as a simple four-cylinder engine can run at up to 24000 revs per minute, meaning that the ignition system will be required to generate around two hundred sparks per second, with each spark at the optimum time to detonate the charge.

The role of the ignition system is simple: to produce a spark to ignite the mixture of fuel and air released by the carburettor and deliver this spark at the correct time. To achieve this is no simple task as a simple four-cylinder engine can run at up to 24000 revs per minute, meaning that the ignition system will be required to generate around two hundred sparks per second, with each spark at the optimum time to detonate the charge.

A car's ignition system comprises just a few parts- all of them simple but together critical.

The first of them is the ignition coil.

The first of them is the ignition coil.

The ignition coil in any car in any vehicle should not be problematic, as it has no moving parts.

This factor should mean that the coil should last for many years trouble-free motoring.

Problems can only begin to appear if the car has been left standing for a long time, during which time the ignition system will start to deteriorate gradually.

More modern cars, especially those fitted with V8 engines and upwards, will utilise two contact-breakers within one distributor to cope with the extra demands of more cylinders.

When carrying out an ignition system renovation, the ignition coil, which is two coils placed inside the other, can be one of the more problematic aspects.

![]()

If an auto-electrician is called in to assess the state of the vehicle's ignition system, they will use a piece of equipment called an ammeter to take a reading of the current produced.

If an auto-electrician is called in to assess the state of the vehicle's ignition system, they will use a piece of equipment called an ammeter to take a reading of the current produced.

In the event of the reading showing three amperes exceeded on an L volt coil, or six for a 6 volt one, then the chances are that the coil is experiencing a partial or even a complete short circuit.

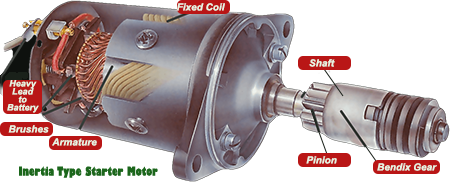

On the other hand if the starter is not turning, then the first deduction should be that the flow of voltage to it is blocked somewhere down the line.

All that is required for the auto-electrician to utilise either a simple live-tester or test lamp connected between various points along the system.

When a "good earth "is picked up, it should rapidly show where the power is flowing.

When a "good earth "is picked up, it should rapidly show where the power is flowing.

If the test fails, it will take just a few seconds to pinpoint the problem and a few seconds more to repair.

Once it has been established that power is arriving safely to the starter motorand it still does not respond, a number of tests can be carried out to analyse the problems before taking the drastic step of dismantling it and sending it for repair or replacement.

If there is no option but to dismantle the motor, the first action is to check it thoroughly for signs of burning on the rotor windings; this would suggest a faulty coil, meaning that the unit will need to be replaced.

Even if the ignition system on the classic car to be renovated is in good condition, it is relatively common for many restorers to improve the ignition system in their classic car.

![]()

A perfect example is to fit the most up to date versions of plugs and leads available.

The reason is that today's plugs and leads will be superior to the original, enhancing the driving experience considerably without affecting the authenticity of the vehicle too much.

A spark plug is one of the most essential components of an auto electrical system, providing the vital spark that ignites the air-fuel mixture that drives internal combustion.

The role of the spark plug is to deliver electric current through a centre electrode from the ignition system to the combustion chamber to ignite the compressed fuel/air mixture delivered by the carburettor while simultaneously suppressing combustion pressure within the engine.

The centre electrode of the spark plug is encased by a non-conductive ceramic insulator designed to prevent any electric current from leakage, thus ensuring that the electricity flows in the proper direction.

The centre electrode of the spark plug is encased by a non-conductive ceramic insulator designed to prevent any electric current from leakage, thus ensuring that the electricity flows in the proper direction.

The central electrode, which often contains an internal resistor, is connected to the output terminal of the ignition coil by a heavily insulated wire.

The outer core of the spark plug is typified by its threaded metal shell, screwed into the engine's cylinder head, creating an electrical ground.

Protruding through the porcelain insulator into the combustion chamber, the central electrode creating a minimum of one spark gap and often more between the inner end of the central electrode and the structures attached to the inner end of the threaded shell is designated to side, earth, or ground the spark plug electrodes.